Why Choose Insulated Shipping Containers for Your Temperature Sensitive Cargo

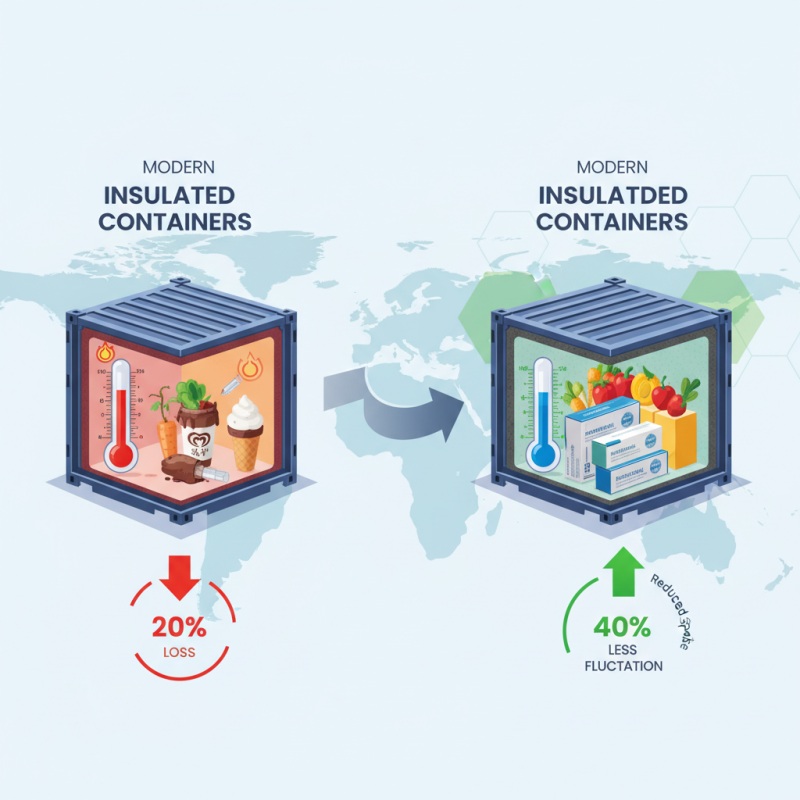

In the ever-evolving landscape of logistics and supply chain management, the significance of maintaining optimal temperature control during transportation cannot be overstated, especially for temperature-sensitive cargo. According to a report by the International Institute of Refrigeration, over 20% of perishable goods are lost due to inadequate temperature management during shipping. This alarming statistic underscores the necessity for reliable and efficient shipping solutions, particularly when it comes to preserving the quality of products such as pharmaceuticals, fresh produce, and other sensitive items.

One of the most effective solutions for addressing these challenges is the use of insulated shipping containers. These containers are designed to provide superior thermal protection, ensuring that the contents remain within the required temperature range throughout transit. Studies have shown that insulated shipping containers can reduce temperature fluctuations by as much as 40%, significantly lowering the risk of spoilage and deterioration. By leveraging advanced insulation technology, businesses can enhance their logistical operations, ensuring that they meet both consumer demand and regulatory standards while minimizing waste and maximizing profits. As the global market for temperature-sensitive products continues to grow, adopting insulated shipping containers is not just a practical choice but a strategic imperative.

Benefits of Using Insulated Shipping Containers for Sensitive Goods

Insulated shipping containers play a crucial role in maintaining the integrity of temperature-sensitive cargo during transport. One of the primary benefits of these containers is their ability to regulate internal temperatures, which is essential for goods such as pharmaceuticals, perishable food items, and certain chemicals that can be adversely affected by temperature fluctuations. The unique insulation materials used in these containers help to create a stable environment, reducing the risk of spoilage and loss of quality while significantly extending the shelf life of the products being transported.

Another notable advantage of insulated shipping containers is their energy efficiency. By minimizing the need for additional refrigeration systems, these containers reduce energy consumption and costs associated with maintaining temperature control. Additionally, their design allows for effective thermal performance without compromising space. This translates to optimized loading capacity and streamlined logistics, making them an appealing choice for businesses looking to enhance their transport operations while ensuring the safe delivery of delicate goods. The durability and robustness of insulated containers also safeguard contents against external conditions, providing peace of mind for shippers and recipients alike.

Benefits of Using Insulated Shipping Containers for Sensitive Goods

This chart illustrates the benefits of using insulated shipping containers for temperature-sensitive cargo. The data reflects the importance of maintaining temperature stability, cost savings, and damage reduction.

How Insulated Shipping Containers Maintain Temperature Control

Insulated shipping containers are specifically designed to maintain a stable internal temperature, which is crucial for transporting temperature-sensitive cargo. These containers utilize advanced insulation materials that minimize heat transfer between the internal environment and external conditions. By effectively keeping out extreme temperatures, they help maintain the integrity of perishable goods, pharmaceuticals, and other sensitive products throughout the shipping process.

The insulation technology employed in these containers creates a thermal barrier that can withstand various environmental factors. This includes insulation from heat in warmer climates and protection from cold during winter months. Additionally, many insulated containers are equipped with advanced features such as temperature monitoring systems that provide real-time data on the internal conditions. This ensures that the cargo remains in optimal conditions, reducing the risk of spoilage or degradation. As a result, insulated shipping containers not only preserve the quality of products but also enhance logistical efficiency by reducing the need for last-minute adjustments or losses due to temperature fluctuations.

Types of Insulated Shipping Containers Available in the Market

When it comes to transporting temperature-sensitive cargo, choosing the right insulated shipping container is crucial. There are several types available in the market, each designed to cater to specific needs and conditions. One popular option is the refrigerated container, which utilizes advanced cooling technology to maintain a consistent temperature. These containers are ideal for perishable goods such as food items and pharmaceuticals, ensuring they remain fresh throughout their journey.

Another option is the thermal shipper, which focuses on insulation rather than refrigeration. These containers are constructed with high-performance insulating materials that help regulate temperature over extended periods without the need for active cooling systems. They are particularly useful for shipping items that are sensitive to temperature fluctuations, such as certain chemicals and biological samples. Additionally, some insulated containers are designed for dry ice shipping, providing a suitable environment for products that require ultra-low temperatures. The variety of insulated shipping containers available ensures that businesses can find the perfect solution for their unique logistical challenges.

Best Practices for Packing and Storing Cargo in Insulated Containers

Insulated shipping containers are essential for protecting temperature-sensitive cargo during transport. When packing materials, it is crucial to consider insulation efficiency. Industry reports suggest that temperature fluctuations can lead to product degradation. For instance, a study by the International Institute of Refrigeration indicates that perishable goods can lose up to 30% of their quality if not maintained at the appropriate temperature. Therefore, maintaining a stable environment in insulated containers is vital for preserving product integrity.

When securing cargo in these containers, use thermal blankets and gel packs to enhance insulation. It is important to avoid direct contact between products and the walls of the container, which can lead to cold spots and uneven temperatures. Proper airflow within the container should also be ensured to prevent moisture buildup, which can adversely affect cargo quality.

**Tips:** Always check the insulation materials for wear and tear before each use, as compromised insulation can lead to significant losses. Additionally, label each container accurately with temperature requirements to ensure that handlers understand the specific needs of the cargo. Lastly, regular temperature monitoring with data loggers can provide real-time updates and help make quick adjustments if necessary.

Cost-Effectiveness of Insulated Shipping Solutions for Temperature Control

Insulated shipping containers have emerged as a cost-effective solution for transporting temperature-sensitive cargo across various industries, including pharmaceuticals, food, and chemicals. According to a recent industry report by MarketsandMarkets, the global insulated container market is projected to grow from $1.2 billion in 2021 to $1.9 billion by 2026, indicating a significant demand for efficient temperature control solutions. This growth can be attributed to the rising need for maintaining product integrity during transit, which insulated containers effectively address through their robust insulation properties that help maintain stable temperatures over extended periods.

Insulated shipping containers have emerged as a cost-effective solution for transporting temperature-sensitive cargo across various industries, including pharmaceuticals, food, and chemicals. According to a recent industry report by MarketsandMarkets, the global insulated container market is projected to grow from $1.2 billion in 2021 to $1.9 billion by 2026, indicating a significant demand for efficient temperature control solutions. This growth can be attributed to the rising need for maintaining product integrity during transit, which insulated containers effectively address through their robust insulation properties that help maintain stable temperatures over extended periods.

The cost-effectiveness of insulated shipping solutions is evident in both operational efficiency and reduced spoilage rates. When compared to refrigerated shipping methods, insulated containers often require lower energy consumption, leading to decreased transportation costs. A study conducted by the International Journal of Logistics Research and Applications highlights that temperature fluctuations during transportation can result in spoilage rates of up to 30% for sensitive goods. By utilizing insulated containers, businesses can minimize these losses significantly, thereby enhancing profitability. With improved insulation technology, businesses can also benefit from longer shipping durations without sacrificing quality, effectively enabling them to explore cost-effective routes that were previously not viable.

Related Posts

-

2025 Top 5 Benefits of Using a 20 Foot Storage Container for Your Space

-

What is a Shipping Container and How is it Used in Modern Logistics

-

Top Uses and Benefits of Cargo Containers in Modern Shipping and Storage

-

Exploring the Advantages of Side Opening Shipping Containers for Your Business Needs

-

Top Benefits of Using Small Shipping Containers for Your Storage Needs

-

Understanding the Costs and Uses of a 40 ft Container in Shipping