2026 Top Cargo Container Trends and Innovations You Should Know?

The cargo container industry is at a pivotal juncture. According to a recent report by Statista, the global container shipping market was valued at approximately $11 trillion in 2022. This figure is expected to grow steadily, driven by e-commerce and global trade expansion. Innovations in cargo containers are becoming essential for optimizing shipping efficiency and sustainability.

Emerging trends, such as the integration of IoT and advanced tracking technologies, are enhancing transparency and security in supply chains. Moreover, reports indicate a shift towards eco-friendly materials and designs, aligning with global sustainability goals. However, challenges remain. The implementation of these innovations is often met with resistance due to cost and complexity.

In the dynamic landscape of cargo transportation, stakeholders must adapt. As we look to 2026, staying informed about these trends is crucial. Investing in modern cargo container solutions may be the key to thriving in an increasingly competitive market. The time for reflection on past practices is now. Embracing change can empower the industry to meet future demands more effectively.

Emerging Technologies in Cargo Container Design for 2026

Emerging technologies are reshaping cargo container design for 2026. With the focus on sustainability, innovators are exploring eco-friendly materials. These materials are lightweight yet strong, reducing overall shipping emissions. Advances in 3D printing further allow for custom designs tailored to specific cargo needs. Flexibility becomes key, as containers evolve beyond traditional shapes.

Smart technology is another game changer. Sensors are being integrated into container designs. These sensors monitor temperature, humidity, and even location. Such data helps track conditions in real-time. It raises questions about data security, though. How safe is this information from cyber threats? The balance between efficiency and risk is a concern.

Modular containers are also gaining traction. This design allows easy stacking and reconfiguration. It maximizes space utilization in shipping lanes. Yet, this innovation demands new logistics strategies. Will current ports adapt quickly enough? The need for a harmonious transition is apparent. Adaptable designs may lead to unforeseen challenges in the supply chain.

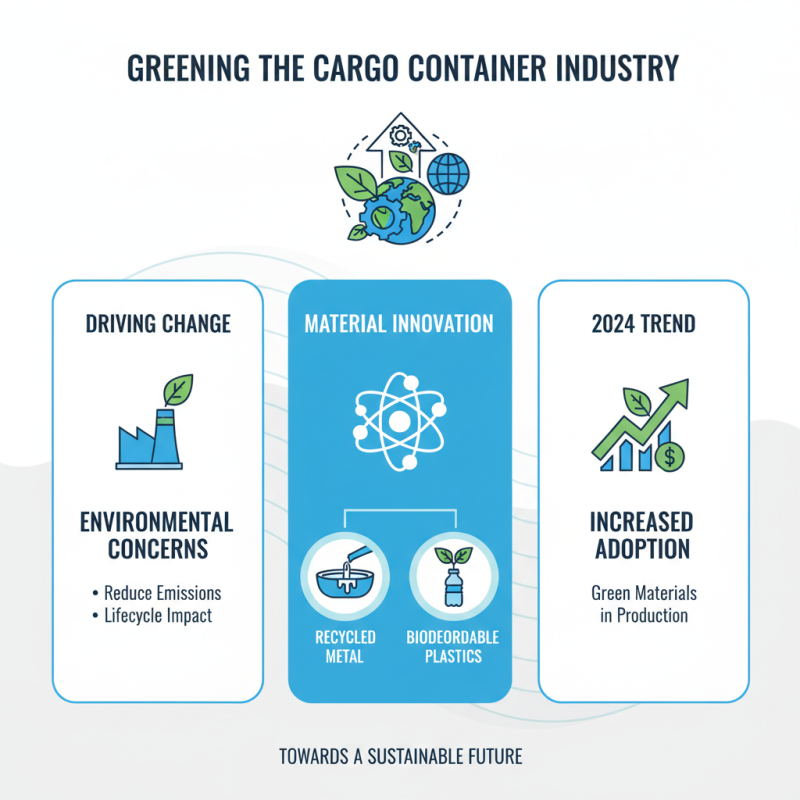

Sustainable Materials and Practices in Container Manufacturing

The cargo container industry is slowly shifting towards sustainability. Environmental concerns are driving manufacturers to explore green materials. This year sees an increase in the use of recycled metal and biodegradable plastics in container production. These materials can reduce harmful emissions during manufacturing and throughout the container's lifecycle.

However, the transition isn't seamless. Many manufacturers still rely on traditional materials that are less eco-friendly. This inconsistency poses challenges for the entire supply chain. Additionally, implementing sustainable practices often means higher initial costs. Many companies hesitate to invest in new technologies due to this financial burden. Striking a balance between cost and sustainability is essential yet complex.

Innovation in container design also embraces sustainability. Modular designs are becoming popular, allowing easier repairs and modifications. These designs can extend the lifespan of containers significantly. Still, adapting to these new designs requires effort and commitment from all stakeholders involved. The journey toward truly sustainable container manufacturing is ongoing and demands constant reflection and improvement.

Smart Containers: IoT Integration and Real-Time Tracking Innovations

Smart containers are transforming the cargo industry. The integration of IoT technology is a game-changer. These containers can provide real-time tracking, improving visibility throughout the supply chain. According to recent studies, companies using IoT in logistics see a 30% increase in operational efficiency. This is crucial as global trade continues to expand.

However, challenges remain. Not all shipping companies have adopted these technologies. In fact, a report indicates that only 15% of shipping containers are currently equipped with IoT devices. This presents a gap between the industry’s potential and its reality. The data also highlights concerns over cybersecurity. Securing sensitive data is vital as more companies rely on digital solutions.

Engaging with these innovations can yield significant benefits. Real-time tracking reduces delays and enhances customer satisfaction. Yet, integration requires significant investment and training. Many companies struggle with incorporating these advanced technologies into their existing systems. The path to smart containers is promising, but it is not without its hurdles.

2026 Top Cargo Container Trends and Innovations

This chart illustrates the projected adoption rates of various innovations in cargo containers by 2026. The data shows that IoT integration and real-time tracking will lead the trends, with significant growth expected across other innovations as well.

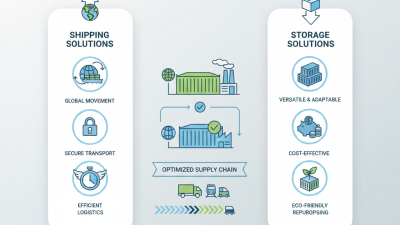

Trends in Modular and Adaptable Container Solutions for Shipping

The shipping industry is increasingly focused on modular and adaptable container solutions. These innovations allow for greater flexibility in logistics. Modular containers can be easily reconfigured to suit different cargo types. This adaptability can lead to efficient space utilization and reduced shipping costs.

One significant trend is the use of interlocking systems that enable containers to be stacked and organized in various ways. This feature not only maximizes loading space but also offers easy access to specific products. However, implementing these systems can create challenges in terms of standardization and safety. There may be inconsistencies in how containers fit together, which can lead to potential risks.

Another area of growth is the integration of smart technology. Sensor-equipped containers can provide real-time tracking and monitoring. This innovation can enhance supply chain visibility and reduce losses. Yet, reliance on technology may raise concerns about data security. Companies must balance innovation with risk management, ensuring that advancements do not compromise the integrity of shipping operations.

The Impact of Autonomous Transport on Cargo Container Logistics

The rise of autonomous transport is reshaping cargo container logistics. One report predicts that by 2026, over 40% of freight movements will utilize autonomous vehicles. This shift could reduce transportation costs by 15%, significantly impacting the supply chain. However, it's essential to recognize potential challenges.

Integration of autonomous systems is not always seamless. Logistics companies may struggle with outdated infrastructure. Many ports still rely on manual processes, which could hinder efficiency. Adapting to new technologies requires time, investment, and training. A staggering 30% of logistics firms noted resistance from their workforce to adopt these innovations.

Safety remains a critical concern. Autonomous vehicles must navigate complex environments. The potential for accidents or system failures could deter some companies from fully adopting this technology. As we move forward, balancing innovation with caution will be crucial. Addressing these challenges opens the door to smarter, more efficient logistics in the future.

Related Posts

-

Top Benefits of Using Cargo Containers for Shipping and Storage Solutions

-

Top Uses and Benefits of Cargo Containers in Modern Shipping and Storage

-

What is a Sea Container and Why Is It Essential for Shipping Logistics

-

Understanding the Economic Impact of Global Trade Through Cargo Containers in 2023

-

2025 Top Digital Innovations Revolutionizing Cargo Storage Containers Industry with Market Insights

-

2025 Top 5 Cargo Storage Containers for Efficient Warehousing Solutions